Superior Performance with Contactless System Reduce Friction and Wear No Replacement Parts Low Maintenance Low Running Costs

Products

Dewlink provides complete sludge dewatering solution and never compromise on the production process, raw materials used, management of projects and quality inspection is at the highest.

Our modular products have many technical advantages over the traditional dewatering equipment. We believe they are more efficient, stable, economical, intelligent, secure, convenient and environmentally friendly. The combination of the MixCycle polymer dissolution device, the Tubox flocculation device and the Swingmill dewatering drum is a landmark in innovation, simplifying the complicated process of sludge treatment.

MixCycle

Automatic polymer make-up system, available for solid and emulsion polymer.

The function of the MixCycle is to dissolve solid or emulsion polymer. The main advantage of the MixCycle is the rotary feeder. It can accurately release equal measures of polymer into the mixing tank. The combination of duel agitator blades and three mixing tanks, allows for effective mixing, avoiding agglomeration resulting in the creation of a stable flocculant solution, which is vital for the forming of a unified floc.

Compared to the traditional polymer mixing device, we believe our design has a shorter curing time with low power usage and a faster dosage speed. It is also easy to maintain with hard wearing components and we always use the highest quality materials for the construction of our units, making them extremely reliable.

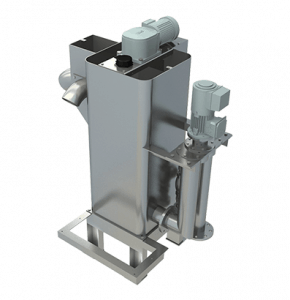

Tubox

Fast and effective flocculation device, improving the quality of floc for better dewatering result.

The unique design of The Tubox will efficiently and effectively mix the sludge and flocculant solution together, to form a unified floc, for the dewatering press to process. The main feature of the device is the high-speed mixing blade which creates a collision effect, allowing the forming of a larger unified and stable floc. The Tubox also has several advantages, it reduces polymer usage, improve sludge handling capacity and the agitator is very energy efficient. The compact modular design makes the Tubox easy to install with a small footprint and the secure enclosure eliminates odour release from the sludge.

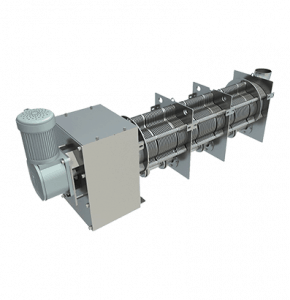

Swingmill

The latest innovation on the many variation of screw press dewatering system, with an increase in durability.

The Swingmill is a much improvement on the many variation of screw based dewatering devices, available on the market. It is based on the consecutive fixed rings and moving rings mechanism. The main difference with our system is that it is powered by external drive rods, creating both a rectilinear motion and a pendulum movement. We can confidently say that this system will be more effective at reducing moisture content of the sludge cake.

The Swingmill is enclosed in a secure casing, making it odour free and it can also run at an extremely low noise level. The durability of the internal components is very high because there is no discharge of steel shavings from the internal rings, as there is no contact between the moving rings and the main screw shaft. Click here to see how the Swingmill can reduce your sludge disposal cost.

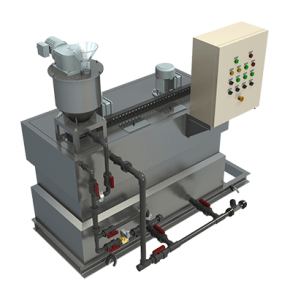

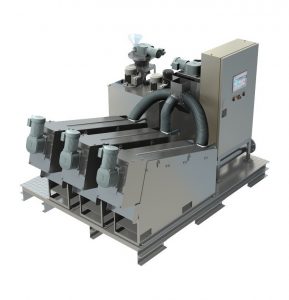

Dewlink Dehydrator

The complete sludge dewatering solution consisting of the MixCycle, Tubox and Swingmill.

The Dewlink Dehydrator is the complete sludge/wastewater solution comprising of the MixCycle, Tubox and the Swingmill. The number and type of module used is dependent on several factors, such as the type of sludge being treated, pre-treatment of sludge requirement, flocculation and customer requirements.

The modular systems allow for easier and faster install times, the compact design occupies little space, making it viable for many situations where space is limited.

Our proposal for any solution are based on field research and the testing of waste water samples. We can offer various packages and solutions for different situations, budgets and needs.

Polymore

Compact and effective liquid polymer make-up systems. Polymore AB is one of the world’s leading manufacturers of polymer make-up units. Polymers are used for sludge dewatering, sludge thickening and for sedimentation in both industrial and municipal plants.

CleanFloc

Both powder and emulsion polymers for creating suitable floc for dewatering. Flocculants is used to promote the clumping of fine particles into a floc. The floc could then be separated from the liquid by floating to the top (flotation), settling to the bottom (sedimentation), or filtered from the liquid (dewatering).

Sludge Treatment Pioneer, Continue to innovate, advance, and exceed, providing customers with a fulfilling experience from design to final installation.

Services For :-

Food & Drinks

Manufacturing

Agriculture & Abattoir

Pharmaceutical & Chemicals

Paper Making

Municipal Waste Water

Mining & Petroleum

Contact Info :-

Dewlink Sludge Treatment Ltd

Unit A1, Hortonwood 10, Telford,

Shropshire, TF1 7ES, UK